In food processing industry, printing industry, textile industry and other manufacturing industries, there is a phenomenon that the manufacturing process depends on tension control. Tension is the pulling force or tension applied on the material, which makes the material stretch in the direction of the applied force. When the tension is too large, the improper tension will cause the material to elongate, break and damage the shape of the roll. If the tension exceeds the shear strength of the material, it will even damage the roll. Insufficient tension will also cause the winding drum to stretch or sag, resulting in poor quality of finished products.

Good tension control can ensure product quality and improve production efficiency. However, for manufacturers, the selection and application of tension control system is very difficult. On the one hand, it is difficult to select the type, the components of tension motion control are complex, and the tension control required by different industries is different, and the type selection is time-consuming, laborious and costly. On the other hand, it is difficult to apply and debug, and engineers have high technical requirements to integrate and debug all parts of the tension control servo system. In order to solve the application difficulties of tension control in various industries, Vicoda has launched the overall solution of tension control.

Overall solution for tension control

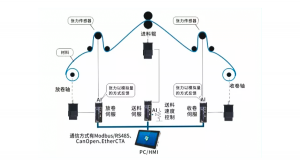

The overall solution of tension control is a special solution developed, customized and integrated for the motion control scenario of tension control. It includes special servo driver for tension control, tension sensor, human-machine interface, and integrates tension controller into servo driver. In short, the overall solution of tension control is to package the operation and control components required for tension control, and customize and optimize them according to the characteristics of tension control.

Based on many years of research and application experience in servo system and motion control, Vecta has launched an overall tension control solution for winding tension control and process tension control required by all production processes, including the following components:

一、 Special servo for tension

The special servo driver has built-in closed loop speed mode, closed loop torque mode, open loop speed mode and open loop torque mode. Without additional programming, different tension control modes can be adopted for different machines, such as open-loop tension control of winding, closed-loop tension control of winding, process tension control, etc., to achieve the effect of high accuracy, high stability, maintenance-free and energy-saving.

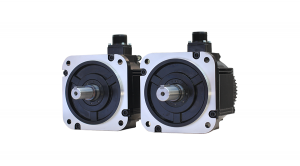

二、 Servo motor

The servo motor is controlled by the servo driver. The overall solution of VEKODA tension control will select and debug the motor in advance according to the three elements of torque, inertia and linear speed motor selection of the system, and package it to the user as a whole, so as to avoid the user’s worries about motor selection.

三、 Sensor

The sensor part includes tension sensor and ultrasonic sensor. When the closed-loop control mode is used, the floating roller type or pressure type sensor is used to feedback the current tension. It should be noted that the analog quantity needs to be calibrated according to the sensor before use. When a deviation correction device is used, an ultrasonic sensor is needed to sense the position of the coil material through the ultrasonic, control the movement of the unwinding or winding shaft forward and backward, and ensure that the position of the coil material does not deviate.

四、 Human-computer interaction screen

The supporting human-computer interaction screen is mainly used to set parameters for the driver (such as tension setting value, cam curve related parameters, etc.), control the driver to enable, jog and return to the original function, and auxiliary monitoring function.

In view of the tension control problems in various industries at present, Vector analyzes the tension control principles and characteristics in different modes, and with 18 years of experience in the research and development and application of servo and operation control industry, realizes the seamless cooperation between product research and development and product application, and provides mature and reliable tension control solutions for all industries!

Post time: Mar-01-2023