In industry, safety is as important as efficiency. Especially in hazardous environments, such as chemical plants, oil RIGS and mines, safety is one of the top considerations. In order to ensure the safety of the working environment, explosion-proof servo motor has become a key technology. But the question is, is the explosion-proof servo motor suitable for all dangerous environments? In this article, we will explore this issue in depth and explain how explosion-proof servo motors work and their applicability in different environments.

1. Understand explosion-proof servo motor

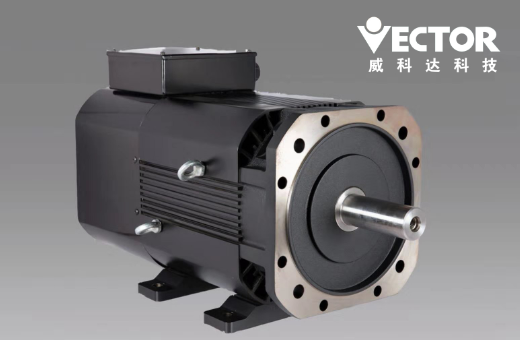

First of all, let’s understand what is explosion-proof servo motor. Explosion-proof servo motors are motors specifically designed for use in hazardous environments where a key feature is the ability to operate safely in the presence of explosive gases or dust. These motors have explosion-proof housing that effectively prevents sparks, arcing, or high temperatures from triggering explosions.

2. Classification of different hazardous environments

Before discussing the applicability of explosion-proof servo motors in depth, let’s first understand the classification of different hazardous environments. According to international standards, hazardous environments can be divided into the following types:

1 Environment with explosive gases

These environments include chemical plants, oil RIGS, etc., where combustible gases such as methane or ethane may be present. In these places, even a tiny spark or electric arc can cause an explosion, so special safety measures are required.

2 Environment with combustible dust

Some industrial sites, such as coal mines or flour processing plants, where combustible dust exists, also need explosion-proof motors to avoid causing explosions.

3 High temperature and high pressure environment

In addition to combustible substances, some dangerous environments may also have high temperature and high pressure characteristics, which puts higher requirements on the tolerance of the motor.

3. Applicability of explosion-proof servo motor

Now, let’s get back to the heart of the matter: Are explosion-proof servo motors suitable for all hazardous environments? The answer is not exactly the same.

1 Suitable for explosive gas environment

Explosion-proof servo motors perform well in environments with explosive gases. They are effective at preventing sparks or electric arcs from triggering explosions, making them ideal for places such as chemical plants and oil RIGS.

2 Suitable for environments with combustible dust

Similarly, explosion-proof servo motors are also indispensable in environments with combustible dust. Their housing is designed to prevent dust buildup and prevent dust from sparking.

3 Challenges of high temperature and high pressure environment

However, in high temperature and high pressure environments, explosion-proof servo motors may face some challenges. These challenges include extreme temperature variations and performance stability under high pressures. Therefore, choosing the right motor in these environments is critical.

Post time: Mar-14-2024